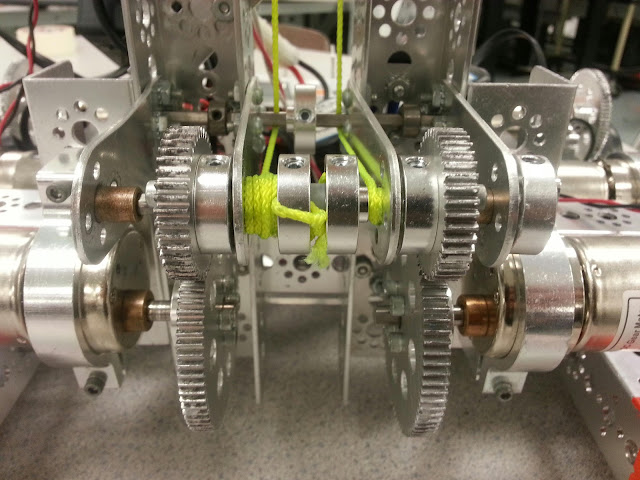

Our lift system for the arm worked beautifully, but we soon realized that we had not allowed enough room in the upper portion of the tower for the arm, which ultimately resulted in the tower and axle getting warped. As our arm had screws and brushing on it, it was actually wider than the gap provided by the two support channels, making them bend apart and bend our axle. We began brainstorming on methods of preventing this, such as supporting the channels to prevent bending or moving each channel a spot over. We finally decided on using two supports connected to a single support with flat brackets in the middle, which provided a sufficient enough space to allow the arm full rotation without any bending. At the same time we edited the lift system and moved the spool outward to allow for easier access and maintenance. The result is the Finger Muncher Mk. II – a beautifully efficient arm and lift system that will happily devour any finger that gets a little too close to it.

11.30.2012

The Finger Muncher Mk. II

Our lift system for the arm worked beautifully, but we soon realized that we had not allowed enough room in the upper portion of the tower for the arm, which ultimately resulted in the tower and axle getting warped. As our arm had screws and brushing on it, it was actually wider than the gap provided by the two support channels, making them bend apart and bend our axle. We began brainstorming on methods of preventing this, such as supporting the channels to prevent bending or moving each channel a spot over. We finally decided on using two supports connected to a single support with flat brackets in the middle, which provided a sufficient enough space to allow the arm full rotation without any bending. At the same time we edited the lift system and moved the spool outward to allow for easier access and maintenance. The result is the Finger Muncher Mk. II – a beautifully efficient arm and lift system that will happily devour any finger that gets a little too close to it.

11.26.2012

Base Instincts

As the channel the motors are mounted on would bend while moving the lift up or down, we attached a second channel next to it that mounts one channel to another, preventing bending or rotation. This makes the motor mounts much stronger and gives the axle less give to slide.

11.21.2012

Coming Together

For the first time in a long while, Sonic is once again ready for testing. We fixed the string system for raising and lowering the lift and moved it so it is easily accessible if it needs to be changed or repaired. While practising with the robot, we noticed that the axle holding the strings would slide, allowing the gears to lose contact with each other. By providing more stabilization to the motor mounts and adjusting the axle, we hope to prevent this from occurring.

11.20.2012

String Theory

What is touchy, fragile, and impossible to maintain? Our string spool, apparently. Whenever our robot decides to break its string – which it does more often then we'd like – it becomes a full day's chore to replace it. A few cramped hands later, we decided we needed a new one. So, as usual, it's back to SolidWorks for prototyping. The new one will move the whole spool assembly out to the back of the robot, making it a lot more accessible and – hopefully – easier to repair.

11.19.2012

Repositioning

In a unanimous vote, we have decided that our current placement of the motor controllers is ridiculous and silly; as such, I have endeavored to devise a new, improved strategy for attaching them, involving one plexiglass sheet, some screws and – by popular vote – some velcro. It should do several things: make the wires neater and more accessible provide additional support for the arm, and allow for there to be velcro on the robot. All is right with the world.

Weekend Recon

11.13.2012

One String to Rule Them All

After no school on Monday, we reconvened today to finally finish up our string system, only to instead attempt to use one string for the whole system, creating a whole new set of problems to solve. The strings would slip on the axle, so we had to tie it through the collar in the middle of the axle. After getting everything strung and ready for testing, we found that a single string would spool too much and become tangled, making all our work pointless. Back to our original two string idea...

11.09.2012

In a Bind

Stringing the robot has proved a much more daunting task than previously believed. Travis built a string separator out of plastic and I reconstructed the assembly, only for my knots to come undone. Casey then attempted it a second time with the exact opposite outcome of knotting it too well and rendering it completely immobile. In response I've researched methods of tying knots and have hopefully solved the problem for Monday, as its too late to get anything else done today.

Subscribe to:

Posts (Atom)