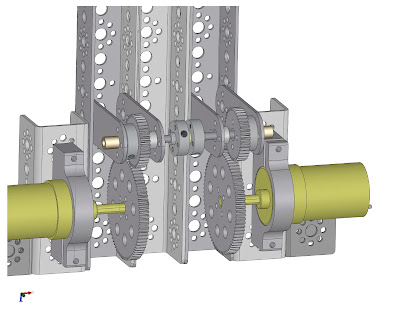

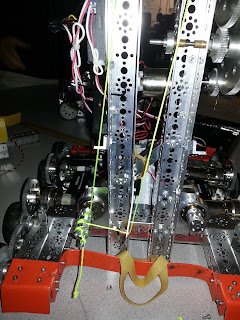

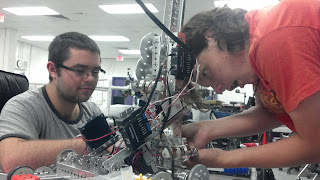

Our lift system for the arm worked beautifully, but we soon realized that we had not allowed enough room in the upper portion of the tower for the arm, which ultimately resulted in the tower and axle getting warped. As our arm had screws and brushing on it, it was actually wider than the gap provided by the two support channels, making them bend apart and bend our axle. We began brainstorming on methods of preventing this, such as supporting the channels to prevent bending or moving each channel a spot over. We finally decided on using two supports connected to a single support with flat brackets in the middle, which provided a sufficient enough space to allow the arm full rotation without any bending. At the same time we edited the lift system and moved the spool outward to allow for easier access and maintenance. The result is the Finger Muncher Mk. II – a beautifully efficient arm and lift system that will happily devour any finger that gets a little too close to it.

11.30.2012

The Finger Muncher Mk. II

Our lift system for the arm worked beautifully, but we soon realized that we had not allowed enough room in the upper portion of the tower for the arm, which ultimately resulted in the tower and axle getting warped. As our arm had screws and brushing on it, it was actually wider than the gap provided by the two support channels, making them bend apart and bend our axle. We began brainstorming on methods of preventing this, such as supporting the channels to prevent bending or moving each channel a spot over. We finally decided on using two supports connected to a single support with flat brackets in the middle, which provided a sufficient enough space to allow the arm full rotation without any bending. At the same time we edited the lift system and moved the spool outward to allow for easier access and maintenance. The result is the Finger Muncher Mk. II – a beautifully efficient arm and lift system that will happily devour any finger that gets a little too close to it.

11.26.2012

Base Instincts

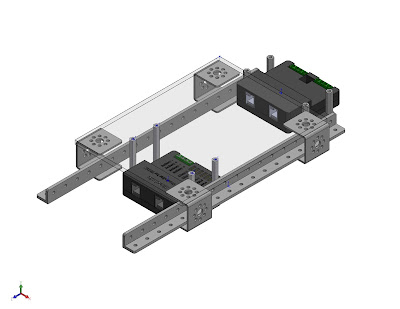

As the channel the motors are mounted on would bend while moving the lift up or down, we attached a second channel next to it that mounts one channel to another, preventing bending or rotation. This makes the motor mounts much stronger and gives the axle less give to slide.

11.21.2012

Coming Together

For the first time in a long while, Sonic is once again ready for testing. We fixed the string system for raising and lowering the lift and moved it so it is easily accessible if it needs to be changed or repaired. While practising with the robot, we noticed that the axle holding the strings would slide, allowing the gears to lose contact with each other. By providing more stabilization to the motor mounts and adjusting the axle, we hope to prevent this from occurring.

11.20.2012

String Theory

11.19.2012

Repositioning

Weekend Recon

11.13.2012

One String to Rule Them All

11.09.2012

In a Bind

Working for the Weekend

Switch 'Em Out

11.08.2012

30 Minutes or Less

Silly String

Feeling Rather Spoolish

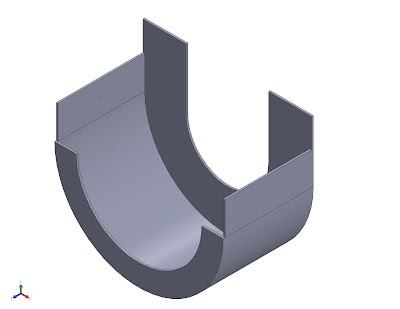

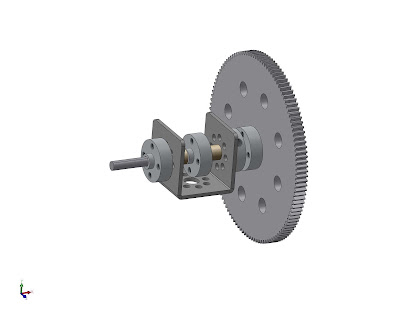

Unlike the last spool – which was mounted on the side – this one goes between the two bars in the arm, meaning that it's a more direct route for the string than before. In addition, the string uses the arm's axle as a pivot, meaning it will always be the correct length regardless of what angle the arm is at. Pretty nifty, I think.

11.07.2012

Going Up

Decoding

11.05.2012

Chutes and ladders

11.03.2012

FTC Engineering Notebook

Cypress Bay High School Did a presentation on the Engineering Notebook and what they did to win the Think award for their notebook from the previous competition. Aspects we learned to add to our notebook are more specific figures about our engineering process and the challenges we face daily.

FTC Programming Workshop

The St. Thomas team presented a power point on the basics of Robot C. They discussed Robot C tools and the programming language, as well as an efficient way to code the robot using comments and functions to clean up and improve the readability.

Proving Grounds

Today is our practise tournament at St. Thomas High School where we can meet other teams and test our robot against theirs in the ring. We can also create friendships and alliances here that will follow us long past this year's FTC challenge, making this a great day for our robot and our team.

11.02.2012

What Really Grinds My Gears...

11.01.2012

Mentorship