11.03.2012

Proving Grounds

Today is our practise tournament at St. Thomas High School where we can meet other teams and test our robot against theirs in the ring. We can also create friendships and alliances here that will follow us long past this year's FTC challenge, making this a great day for our robot and our team.

11.02.2012

What Really Grinds My Gears...

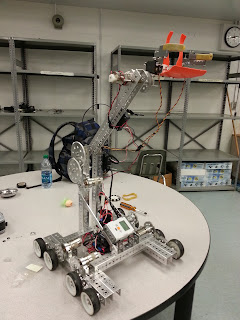

The arm design we used to reach the second level of the rack had a gear ratio of 25 to 1 in order to provide the power we needed to reach the height with the weight of the grabber. An unfortunate side effect of this gear ratio is the large amounts of stress it puts the parts under. We experienced this first hand when the axle our arm was on was twisted and bent by the force, forcing us to cut it in order to replace it with a new axle that can better handle the stresses.

11.01.2012

Mentorship

Casey went to Western High School to help mentor the rookie team that visited us the other day after school.

10.31.2012

Here It Goes Again

Casey and I stayed afterschool today to practise with the robot and our new arm as we have a practise tournament on Saturday, November 3. This is one of our runs, timed at a two-minute period. After repeated practise we got our best to be 12 rings placed on the middle rack, and developed a strategy to get the most rings in the least amount of time.

Not another brick in the wall

Today, we were visited afterschool by Western High School's FTC rookie team. We showed them our set-up and gave them valuable knowledge about designs and coding. Our team really hit it off with their group and we exchanged contact information in order to provide further assistance to our hopefully future competitors.

Armageddon

The arm is now finished and ready for testing. This arm needs to be able to grab rings from the first level and deposit them onto the second level of the rack, all while maintaining balance and structural integrity. The arm can move up and down and the grabber on the end can rotate, giving us the degrees of movement we need in order to place the rings.

10.30.2012

Growth Spurt

We removed the previously short aluminium channel and replaced it with a longer channel that can reach the middle level of the rack. In order to do this, we had to remove our cross support and brain mount, meaning we'll have to find a new location for them. Additionally, we will have to add an additional motor to the channel that will enable the grabber to rotate to grab and release rings.

Subscribe to:

Posts (Atom)